What Is an Energy Management Information System?

Overview

An Energy Management Information System (EMIS) is an important element of a comprehensive energy management program. It provides relevant information to key individuals and departments that enables them to improve energy performance.

An EMIS can be characterized by its deliverables, features, elements and support. Deliverables include the early detection of poor performance, support for decision making and effective energy reporting. Features of an EMIS include the storage of data in a usable format, the calculation of effective targets for energy use, and comparison of actual consumption with these targets. Elements include sensors, energy meters, hardware and software (these may already exist as process and business performance monitoring systems). Essential support includes management commitment, the allocation of responsibility, procedures, training, resources and regular audits.

This section outlines what constitutes an effective EMIS. The checklist in Section 10 will help determine whether a proposed or existing EMIS will succeed. Questions addressed in this section are summarized in Figure 1.

Figure 1. Basics of an EMIS

2.1 What Is an EMIS?

An EMIS provides information to appropriate personnel within an organization to help them manage energy use and costs. The exact nature of the EMIS will depend on

- the particular site

- the processes and plant involved

- the cost of energy (in relation to other costs)

- existing meters and instruments

- monitoring and control systems

- the data historian

- data analysis and reporting systems

- existing management systems

In this handbook, an EMIS is defined principally in terms of what it delivers to the organization; how the deliverables are achieved is secondary.

Over the years, EMISs have been implemented with varying levels of success and sustainability. The checklist in Section 10 outlines what constitutes an effective EMIS, i.e., one that will reduce energy costs by at least 5 percent and sustain that improved performance. Readers should ensure that their proposed or existing EMIS meets these requirements (examine each of the items in the checklist).

This handbook discusses the components in the checklist in some detail, and we strongly suggest that readers revisit the checklist once they have studied this handbook.

2.2 Energy Management Programs and the EMIS

An Energy Management Information System (EMIS) is only one element of a comprehensive energy management program (EMP), albeit an important one without which full benefits will not be achieved and sustained. A good EMIS should reduce energy use (and cost) by at least 5 percent.

Actions that generally need to be taken in order to address energy use in an EMP may include one or more of the following:

- developing and approving an energy policy and strategy

- training and actions to raise knowledge and awareness

- energy audits to identify and evaluate opportunities

- developing and implementing improvement opportunities

- implementing performance management systems, including the EMIS

Figure 2. Elements of an energy management program (EMP)

An organization's energy policy should have agreed-upon objectives and demonstrate senior management's commitment. The policy's energy strategy should outline specific plans to achieve improved performance.

Training is essential to ensure that operations personnel understand key energy issues and what actions they need to perform in order to reduce costs. Activities to raise awareness can also be used to emphasize the need to reduce energy use and make the link between energy and the environment.

Energy audits are traditionally the foundation of an organization's energy conservation plan. Audits are usually carried out by experienced engineers and identify and quantify where energy is used and find measures for improvement. These measures may be low- or no-cost changes or require capital investments.

Once opportunities are identified, they need to be developed into projects that can be justified and implemented. Developing the project includes accurate estimates of costs and benefits and assessments of practical, safety and environmental issues.

Performance management systems aim to ensure that benefits are achieved and sustained through monitoring, performance analysis and effective reporting to all levels of an organization.

An EMIS is the key element of performance management; it also provides essential support to the energy auditing process. A modern EMIS will be a software solution that is tightly integrated into an organization's systems for process monitoring and control and IT systems. Furthermore, the EMIS will often be part of a larger system used to manage process (and business) performance more generally.

It is important to recognize that an EMIS does not stand alone. It needs management commitment, procedures, organization, training and appropriate technical expertise.

2.3 What Does an EMIS Deliver?

The principal objective of an EMIS is to support an organization's energy management program. Its specific deliverables are as follows:

- 2.3.1 Early detection of poor performance

- 2.3.2 Support for decision making

- 2.3.3 Effective performance reporting

- 2.3.4 Auditing of historical operations

- 2.3.5 Identification and justification of energy projects

- 2.3.6 Evidence of success

- 2.3.7 Support for energy budgeting and management accounting

- 2.3.8 Energy data to other systems

Understanding what an EMIS can deliver is vital if an effective system is to be designed and implemented. Based on the following discussion, readers should be able to specify the requirements of an EMIS for their particular site.

2.3.1 Early Detection of Poor Performance

A key deliverable of an EMIS is that it will identify poor operations quickly and effectively. Examples are:

- incorrect control set-points

- equipment left operating unnecessarily

- faults with equipment, for example, heat exchanger fouling, air in refrigeration condensers, etc.

Such faults should be identified as quickly as possible and corrected with practical and cost-effective solutions. It is not sufficient to detect a problem that has occurred in the past (for example, last week) that cannot now be rectified because too much time has elapsed and operations have moved on to a new "mode."

Comparing actual performance with targets generally identifies poor performance. A deviation from the target causes an alert. Performance indicators include energy consumption, but can also include measures of efficiency and indirect indicators of performance (for example, the oxygen level in a boiler's exhaust).

Targets can be defined in a number of ways, all of which can be usefully applied. Examples are:

- the performance typically achieved by the process in the past – current and future performance can be measured against this to demonstrate progress (benchmark)

- the best performance that the process could achieve or has achieved in the past (best practice)

- a desired level of performance, for example, 5 percent below the benchmark (reduction)

- budget performance (budget)

Key to success is that targets are sound, taking full account of relevant influencing factors. This is discussed in detail in Section 8.

The frequency of performance monitoring will vary depending on the application. In a complex process that uses a lot of energy, reporting every 15 minutes may be appropriate, especially where the operator can make process changes in response to performance alerts. On the other hand, an EMIS associated with a central refrigeration unit, for example, may report only daily or weekly because faults are likely to be slow to develop and be rectified only through maintenance actions (for example, condenser cleaning, refrigerant charging, etc.).

Figure 3. Operations report showing poor performance

Figures 3 and 4 show examples of reports that identify performance. Shown in Figure 3 is an alert that the last 10 minutes of performance is poor. Shown in Figure 4 is a shift performance summary showing performance that is improving.

Figure 4. Operations report showing improving performance

Table 1 lists examples of typical problems and their respective monitoring frequencies that a performance monitoring system can identify.

Table 1. Examples of typical problems that cause higher energy costs |

Typical Problems | Monitoring Frequency* |

| Process Operations |

|

| - incorrect set-points | hourly |

| - fouled heat exchangers | daily |

| - advanced controls switched off | hourly |

| - poor control timing | hourly |

| Boilers |

| - poor air-fuel ratio | hourly |

| - fouled exchangers | daily |

| - excessive blow-down | hourly |

| - incorrect boiler selection | hourly |

| Refrigeration |

| - fouled condenser | daily |

| - air in condenser | daily |

| - incorrect superheat settings | daily |

| - high head pressure settings | daily |

| - incorrect compressor selection | hourly |

| Compressed Air |

| - leaks | daily |

| - poor compressor control | daily/hourly |

| - incorrect pressure | hourly |

| Steam |

| - leaks | hourly |

| - failed traps | hourly |

| - poor isolation | hourly |

| - incorrect set-points | hourly |

| - low condensate return | hourly |

| Space Heating/Cooling |

| - excessive space temperature | hourly |

| - excessive fan power use | hourly |

| - overcooling | hourly |

| - heating and cooling | hourly |

| - high chilled water temperature | hourly |

| Power Generation |

| - poor engine performance | hourly |

| - incorrect control settings | hourly |

| - poor cooling tower operation | hourly |

| - fouled heat exchangers | hourly |

| * Appropriate monitoring frequency depends on the application. |

2.3.2 Support for Decision Making

Often, alerting operational personnel and management to poor performance is enough to solve a problem. Such personnel may be experienced enough to understand the reasons for higher energy use and take appropriate remedial action. On the other hand, they may not have the needed experience or sufficient time to conduct an analysis.

Where there is a difficulty in deciding how to act on a problem, decision support systems should be considered as part of an EMIS. Such systems provide supporting information and can take several forms, from guides and charts to sophisticated computer systems.

The "knowledge" within these decision systems can be either

- from experts (expert systems, or knowledge-based systems); or

- learned from operating data (data mining).

The more complex and energy intensive the process, the more likely a decision support system can be justified.

Example 1. Brewery Refrigeration Expert System A large brewery implemented an expert system to provide decision support to utility plant engineers to help them respond to sub-optimal refrigeration performance. The result was a 29.5 percent reduction in electricity consumption by the refrigeration system. The payback period for the system was well under one year. The refrigeration plant provided chilled secondary refrigerant at approximately 23.5°C to the brewery to cool process streams, vessels and cold rooms. The energy use efficiency of the refrigeration systems was significantly affected by - the secondary refrigerant temperature

- evaporator operation, especially fouling and the level of refrigerant

- refrigerant leaks

- expansion valve settings

- condenser performance, especially fouling and the buildup of air and non-condensable gases

- head pressure set-points

- cooling tower performance

Problems had been occurring from time to time, but they had not been specifically identified. Monitoring energy use against targets and using the expert system rectified this. Diagnosing the cause of high energy use is a relatively complex task; the key performance indicators will vary with cooling demand, secondary refrigerant temperature, ambient temperature and humidity. Analysing the situation involves - modelling refrigeration system operation to determine expected operating conditions

- comparing actual values with the model expectations

- interpreting deviations (for example, the presence of air or non-condensable gases is indicated if the condensing pressure is high or if the liquid sub-cooling is high) Although engineers can work through this analytical process, few have sufficient time to do so. The expert system automated the task and rapidly diagnosed the problem.

Today, developing and implementing expert systems is relatively easy. Establishing "rules" for such systems should not be difficult or complex; it is necessary only to apply simple rules consistently, accurately and quickly. |

Recently, decision support systems have been implemented where "rules" are learned from historical operating data. In these cases, the system tells the operator how to modify process operations in order to achieve the best performance levels observed in the past (see Figure 3). This ensures that operations employ consistent best practices.

Figure 5. Report with instructions on how to achieve optimum operating conditions

Figure 6 illustrates the concept of learning from data. Operating periods in the past that were similar to current operations (i.e., similar external disturbances such as production levels, quality, ambient conditions, etc.) are found. The best performing periods are then identified and used to determine the best set of operating conditions. In some circumstances, a simple paper-based system (based on experience or theory) can be useful.

Figure 6. Learning from data

In general, capturing knowledge about operations performance is worth serious consideration. This knowledge should be made readily available within the organization (for example, via corporate intranets).

2.3.3 Effective Performance Reporting

In addition to reporting problems to operations staff, the EMIS should also provide reports to management, executives, engineers and other key personnel (see Section 7). This is to ensure that the appropriate resource(s), commitment and expertise are applied to energy use efficiency. It is a key part of the management process to ensure that those responsible for performance are taking effective action.

Figure 7. Example of management report, showing weekly progress

Figure 8. Example of executive report, showing monthly progress

2.3.4 Auditing of Historical Operations

As well as providing ongoing information about the current energy performance of processes and equipment, an EMIS can be used to analyse historical performance. To do this, the EMIS needs a database of historical energy information and influencing factors. With modern data analysis techniques (see Section 8) this data can provide

- an audit of historical operations (what has happened)

- an explanation or variations in energy performance (why energy use varied)

- an audit of energy use and costs (what operations cost)

From this analysis, engineers and managers can improve their understanding of energy use efficiency, leading to better decisions.

Figure 9. Example of frequency distribution

The EMIS facilitates the understanding of energy performance variations. In Figure 9, the frequency distribution shows that energy costs vary considerably about the mean. Is this due to external factors or to decisions made by plant operations and management personnel? |

The "what has happened" factor is especially important in order to challenge under-performing areas (see Figure 10).

Figure 10. The EMIS should quantify energy use and costs

2.3.5 Identification and Justification of Energy Projects

An EMIS can be the foundation for identifying and justifying energy use efficiency projects. Improvements to operations and control settings can be identified using historical operating data with advanced analysis techniques (see Section 8). These improvements tend to be low- or no-cost "quick hits" and are especially attractive because they can quickly justify investment in an EMIS. Often it makes economic sense to conduct this analysis as a first step.

Analysing historical data can also reveal opportunities that require investment. Importantly, the data available from a correctly configured EMIS can

- challenge barriers to energy projects, including disagreement about how the plant is operated (e.g., is it operated close to a process or marketing constraint?)

- quantify improvements and allow energy investment to be justified

2.3.6 Evidence of Success

The EMIS must clearly show that actions taken to reduce energy use and costs have been successful (or not!). This is to justify ongoing investment in the systems, validate energy-saving decisions, demonstrate the improvements achieved and satisfy regulatory and voluntary reporting, etc.

To do this, there should be a benchmark – a value for energy use that can be compared with current usage. The benchmark must take into account external influences on energy use (production, ambient temperature, etc.). Typically, the benchmark is a model built from historical operating data. Regression is sometimes acceptable, but analysis techniques that are further advanced are more often needed (see Section 8).

A cumulative sum (CUSUM) graph can show improved performance effectively.

Figure 11. Graph showing cumulative savings achieved since an EMIS was installed

2.3.7 Support for Energy Budgeting and Management Accounting

An EMIS provides information to facilitate budgeting. Historical relationships between production and energy use can be used with production estimates to forecast future energy use.

The EMIS will also provide a breakdown of energy use and cost by product, process or department in order to

- improve management accounting;

- determine the true cost of energy, for example, to make specific products; or

- understand the impact of production volumes on energy cost per tonne of product.

2.3.8 Energy Data to Other Systems

An EMIS may also provide energy data and models to other systems. Examples are production planning and scheduling systems, energy, resource planning systems, management information systems, corporate systems and environmental reporting, etc.

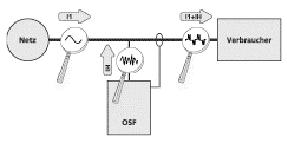

2.4 What Are the Elements of an EMIS?

An EMIS comprises a number of elements that are integrated to form a complete solution. These elements include sensors and instruments, data infrastructure and software tools. Typically, separate suppliers will provide individual modules of the system.

As far as possible, EMIS components will be the same as those used to operate and manage the plant and process performance more generally, i.e., the performance management information system. There is a danger in developing an independent system for energy alone, and this approach has resulted in failures in the past. Energy use efficiency is only one aspect of process (and business) performance and should be considered in conjunction with other business objectives such as output, yield, quality, reliability, environment and profit.

In addition to hardware, the EMIS includes management systems to ensure that performance improvements are achieved.

It may well be that the elements of an EMIS already exist within an organization but are not employed to manage energy use.

Sensors and instruments include energy meters (electricity, gas, oil, steam), other utility meters directly associated with energy use (heat flow, cooling flow, compressed-air flow) and temperature, pressure, flow, composition and similar devices used to measure factors that influence energy use.

The sensors and instruments will usually be connected to a monitoring system, which should always be the monitoring and control system used for the process generally. This may be a distributed control system (DCS) in larger installations or a SCADA/PLC installation. In commercial installations, building management systems are used that are similar to SCADA/PLC.

Data collection should be automated. A data historian that is designed for time-series data storage is typically used. Manual data collection is considered all but obsolete.

Software tools that form an EMIS typically integrate directly with the control/monitoring system and data historian. These include:

- data analysis tools

- reporting tools

- monitoring software

- optimization and decision support software

Interfaces between these tools and the control/monitoring and data historian systems are standard and generally simple to implement. Typically, the EMIS and process monitoring and management infrastructure will be networked with the corporate IT systems. Figure 12 illustrates the elements of a typical EMIS.

Figure 12. Elements of a typical EMIS

2.5 Solutions for Different Circumstances

The features, benefits and elements of the EMIS should be appropriate to the specific site. At a larger, energy-intensive site where there is a modern monitoring and control infrastructure, all the capabilities described in this handbook will be needed. At a smaller site, however, there may be a case for less comprehensive instrumentation, less frequent monitoring and reporting, and less sophisticated analysis of data. This handbook allows readers to choose system elements that are appropriate for their situations. The optimum solution depends on

- the importance and level of energy cost savings achievable

- the rate at which faults can develop and the time required to act on them

- the existing infrastructure that the EMIS can utilize

- the capital available for investment in the EMIS

Many companies that have developed a vision for an EMIS are obliged to move ahead in stages, earning the capital for the next step from savings realized. In terms of system requirements, there is little difference between an EMIS that is used in the industrial sector or the commercial sector, although its implementation may differ. For example, monitoring in the commercial sector will typically involve the building management system, and more responsibility will rest with facility operating personnel to reduce energy use, although feedback from building occupants should be factored into consideration.

Multi-site organizations may want to introduce a corporate EMIS to report centrally and analyse the organization's energy performance as a whole. To achieve this, data historians at each site should be linked, and the analysis and reporting tools should be able to access the combined data. There may be an additional central database of selected information. In addition to providing corporate energy reports (total company energy use vs. targets, for example), it may be possible to analyse corporate data to reveal higher-level patterns in energy use. For example, where several sites operate processes that are similar, it may be possible to find best-practice operating systems and conditions, optimum maintenance, best contractors, best equipment types and suppliers, etc.

This is an extract from“ACHIEVING IMPROVED ENERGY EFFICIENCY” - A handbook for managers, engineers and operational staff, Published by the Office of Energy Efficiency of Natural Resources Canada.

Full text is available at

http://oee.nrcan.gc.ca/publications/industrial/EMIS/index.cfm?text=N&printview=N#contents